Precision and accuracy are crucial in manufacturing processes, where precise measurements and calculations ensure the quality and consistency of products. One common conversion encountered in manufacturing is the conversion between milliliters (mL) and milligrams (mg). Understanding and correctly converting between these units of measurement is vital for proper formulation, dosing, and quality control. In this article, we will explore the role of mL to mg calculator in manufacturing processes and its significance in ensuring product integrity.

You Can Also Read: Application Tracking System for High Volume Recuriting

Understanding mL and mg in Manufacturing:

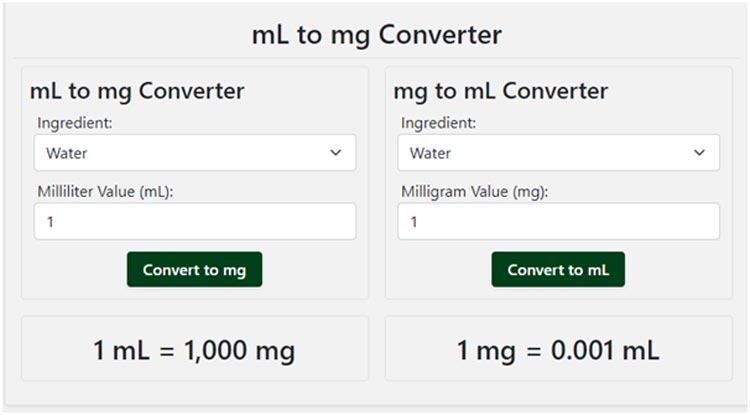

In the manufacturing industry, mL and mg are used to measure different properties. Milliliters (mL) measure volume, often referring to the volume of liquids or solutions used in manufacturing processes. Milligrams (mg), on the other hand, measure the weight or mass of substances, such as raw materials, active ingredients, or additives. Converting between mL and mg is essential for accurate ingredient dosing, formulation calculations, and quality control measurements in manufacturing.

Applications of mL to mg calculator in Manufacturing Processes:

Formulation and Dosing

Many manufacturing processes involve formulating products with precise ingredient concentrations. This is especially true in industries such as pharmaceuticals, cosmetics, and food production. Ingredients may be specified in mg, while the desired formulation requires measurements in mL. Accurate mL to mg calculator is necessary to ensure the correct amount of each ingredient is added to achieve the desired concentration and maintain product consistency.

Quality Control and Testing

Manufacturing processes often require quality control testing to ensure product integrity and adherence to specifications. This may involve testing raw materials, intermediate products, or final products for ingredient concentrations, purity, or potency. Results are typically reported in mg per mL or mg per unit volume. Accurate mL to mg conversion ensures that the measured concentrations align with quality standards and meet regulatory requirements.

Dosage Determination

In industries such as pharmaceuticals and veterinary medicine, accurate dosage determination is critical. Healthcare providers rely on proper mL to mg conversion to determine the appropriate dosage for patients based on weight, age, or specific treatment requirements. Precise conversion ensures that patients receive the correct amount of medication or active ingredient, leading to effective treatment and optimal patient outcomes.

Equipment Calibration

Manufacturing equipment, such as pumps, mixers, or dispensers, may be calibrated based on specific mL to mg ratios. Calibration ensures that the equipment dispenses the correct amount of material or solution during production. Accurate conversion is necessary during calibration processes to maintain consistent and accurate dosing, reducing waste and ensuring product quality.

Importance of Accurate Conversion:

Accurate mL to mg conversion plays a vital role in maintaining product integrity, consistency, and quality control in manufacturing processes. Errors in conversion can lead to underdosing or overdosing of ingredients, resulting in product variations, reduced efficacy, or even safety concerns. Accurate conversion ensures precise formulation, proper dosing, and reliable quality control measurements, which are essential for manufacturing processes to meet regulatory requirements, deliver consistent products, and safeguard consumer trust.

Conclusion:

Accurate mL to mg conversion is a crucial aspect of manufacturing processes across various industries. Precise conversion between these units of measurement ensures proper ingredient dosing, formulation calculations, dosage determination, and quality control measurements. By understanding the role of mL to mg conversion and employing accurate conversion practices, manufacturers can maintain product consistency, quality, and compliance with regulatory standards. Accurate conversion contributes to the overall success, efficiency, and reputation of manufacturing processes, enabling the delivery of high-quality products to consumers.